Key Clamp Fittings

A Versatile, Simple and Durable method of Constructing Handrails, Guardrails and Barriers

Should you wish to purchase our range of Key Clamps, please visit our webstore: www.keyclampsonline.co.uk

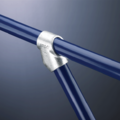

The Key Clamp Range of Slip-On Fittings

- Typical Uses Include: Handrail Constructions, Guardrails, Balustrades, Railings and Safety Barriers.

- Versatile System: Ever growing range of fittings to suit a vast number of tubular constructions.

- Simple to Construct: No special skills required to install. No pre-fabrication, welding or threading is required – the only tool necessary is an allen key.

- Durable: High Corrosion Resistance, Hot Dipped Galvanised Cast Iron to BS EN ISO 1461:1999.

KEY CLAMPS

Key Clamp Fittings Manufactured to BS EN 1562 1997

Hot-Dipped Galvanized to BS EN 1461 1999.

What are Key Clamps?

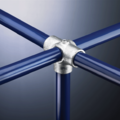

Key Clamps (also known in the industry as ‘tube clamps’ or ‘pipe clamps’) are malleable iron castings, hot-dipped galvanised to BS EN 1461:1999, that are suited to a diverse range of tubular-based applications / constructions, appropriate for both interior and exterior environments.

Applications:

Available in 5 different sizes 26.9mm, 33.7mm, 42.4mm, 48.3mm (Scaffolding size) or 60.3mm (you may also like to refer to tube sizes), Key Clamp fittings are typically used in the industry for the construction of:

- HANDRAILS

- GUARDRAILS

- BALUSTRADES

- RAILINGS

- SAFETY BARRIERS

- RACKING

- TROLLEY BAYS

- CAGES

- LIGHTING GRIDS

- LOADING BAYS

- SHOP DISPLAYS

- FIRE ESCAPES

- BANNER HOARDINGS / ENCLOSURES

- CYCLE HOOPS

- TYRE RACKING etc.

as both permanent and temporary installations in industrial / commercial environments (please see our gallery for examples of Key Clamp installations).

Available to Suit Tube Sizes 26.9mm, 33.7mm, 42.4mm, 48.3mm and 60.3mm O/D.

Due to their significant usage in the construction of handrails, IPM Fittings Ltd stock a Key Clamp Modular Pre-Assembled Handrail / Railing Kit System. This system has significantly increased the speed of installing subsequently reducing the labour costs to our customers.

Due to the incredible versatility of the system, Key clamps also have a wide number of residential / domestic uses. For example some customers require handrails for exterior locations such as the garden. This type of application is particularly relevant to the elderly or those who suffer with ailments such as arthritis.

Whether you need:

- A Handrail for outdoor Steps

- Custom built heavy duty racking for shed or garage – height and width specified to suit your needs.

- Custom made furniture such as a table or a bed

- A heavy duty clothes rail etc.

We are confident that we can supply a cost effective solution for your requirements. Please do not hesitate in contacting us with any questions that you may have.

- Versatile / Flexible: Ever-growing range of fittings, in a number of sizes, to suit a vast number of tubular constructions.

- Cost Effective: Key Clamps are a cost effective means of tubular constructions, as opposed to a bespoke construction.

- Ease of installation: No special skills required to install. No pre-fabrication, welding or threading is required – the only tool necessary is an allen key.

- Durable: High corrosion resistance, Hot Dipped Galvanised Cast Iron to BS EN ISO 1461:1999

Installation:

The design of the Key Clamp system makes constructions a straightforward task with no requirement for specialist tooling.

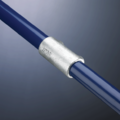

Key Clamps are used in conjunction with galvanised steel tubing. The Key Clamps are secured to the tube by means of hexagon socket set screws, which are tightened using an allen key or ratchet spanner to establish a firm lock between the clamp and the tube. The sharpened edges of the socket set screws effectively ‘bite’ into the surface of the tube creating a solid connection.

Manufacture:

Key clamp fittings are blackheart malleable iron castings manufactured to the requirements of BS EN 1562 1997 and are hot-dipped galvanised to BS EN 1461:1999 and are supplied with pre-fitted socket set screws (aka ‘grub screws’).

Loadings / Reguations:

When tightened to 4.1kg (29 ft/lb) a slip load of 900kg can be achieved on each screw.

If the load is desired to be increased, additional Key Clamps (such as the A058 Collar) can be installed directly under the initial load bearing clamp to achieve an enhanced load capacity. The 3/8" Square Drive Ratchet spanner (reference A074) should be used to tighten the screws to the required torque.

There are many standards and regulations which are applicable to many common uses of Key Clamps. Please contact us with any questions that you may have.

Other:

Key Clamps are supplied in a galvanised finish. We also offer a powder coating service through which the Key Clamps and / or tube can be supplied in a RAL colour of your choice. When applied to a galvanised finish, powder coating provides a long lasting, low-maintenance and colourful finish ideal for a multitude of applications (please contact us for more information regarding this service).

IPM Fittings Ltd also supply complimentary items which can be used in conjunction with Key Clamps in order to achieve the desired construction. Please refer to Key Clamp Handrail Modular Railing Kits, Scaffold Fittings, Galvanised Tubing and associated protective padding, Rotaclamp heavy duty clamp fittings, Chain, U-bolts and shackles, Galvanised Mesh Infill Panels and fixing bolts.

Purchasing:

Please contact the Company for further information, quotation requests or order placement on the following:

T: +44 (0)20 8689 0777

Disclaimers:

If you are in any doubt as to the suitability of any fittings for your project please feel free to contact us. You should always consult with a qualified engineer should you have any doubts as to the suitability of any construction / application.